How Geometric Turbocharger Works?

How Geometric Turbo charger Works?

Model: Hyundai Engine

| 2011 D 2.0 CRDI Engine Engine Control P0234 Turbocharger/Supercharger Overboost Condition |

|

Bottom of Form

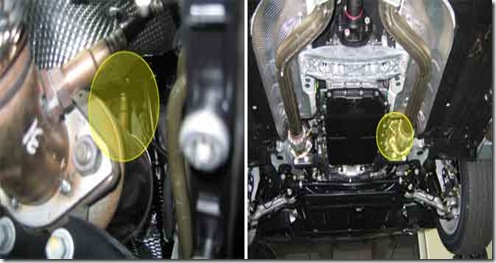

Study VGT(Variable Geometric Turbocharger) is the device which increases the efficiency of turbocharger at low rpm and lasts optimum turbo efficiency at high rpm as varying the cross sectional area through which exhaust gas passes turbocharger impeller. It relieves turbo lag at low speed and increse engine power generation. Study Engine speed, APS signal, MAFS and Boost pressure sensor data are inputted to ECM. Study ECM actuates vacuum diafragm which controls exhaust gas line as controlling VGT actuator duty to maintain optimum state of air compression.

Study P0234 is set when real boost pressure is much lower than target boost pressure for more than 15 sec. at above 1750RPM and 10~22mg/hub of fuel injection quantity. Study This code is due to poor connection of VGT solenoid valve vacuum hose, vacuum leakage, clogging, VGT turbo charger component failure.

Fig.1) VGT actuator output waveform at 79% duty( (-)duty ). Duty decreases as boost pressure increases. Fig.2) VGT actuator duty( (-)duty ) decreases as accelerating. |

![clip_image004[4] clip_image004[4]](http://lh4.ggpht.com/_3gZHoxMA7C0/TPvVk6FVyAI/AAAAAAAABqQ/tz5KKolpqwY/clip_image004%5B4%5D_thumb%5B2%5D.jpg?imgmax=800)

![clip_image005[6] clip_image005[6]](http://lh5.ggpht.com/_3gZHoxMA7C0/TPvVm35Kx-I/AAAAAAAABqY/jS_dYBOFNd8/clip_image005%5B6%5D_thumb%5B3%5D.gif?imgmax=800)

![clip_image006[5] clip_image006[5]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjRyERfc_KvBMoAEFk5QQUDD3xiyp1FQCjK3PgpZGPkbhnqjIQ6FQi-YDxVoSx3bCzYWmGzE6Upb_dC2yRCvDMXy3RbyTHy8BkVBfL5ErmVQ8LkrP96Q6wlmncmNfqdv_SaVi3SiXKKsRfE/?imgmax=800)